Zhuhai Vmaxx industrial equipment manufacturing Co., Ltd

We are a company dedicated to the production and research and development of various lubrication equipment and accessories, pumps, pipelines, joints, self-control components, and other products. We have a complete and scientific quality management system. Adhering to the service concept of "lubrication creates value", driven by customer needs, we continuously implement technological innovation and provide customers with competitive lubrication equipment solutions. At the same time, with convenient and fast professional services, we continue to create maximum value for our customers! The integrity, strength, and product quality of Zhuhai Weirunma Industrial Equipment Manufacturing Co., Ltd. have been highly recognized by the industry. We welcome friends from all walks of life to visit, guide, and negotiate business.

VMAXX®️Service Commitment

service network nationwide. Through careful training and strict management of after-sales service engineers and customer service representatives, as well as full process control of repair, maintenance, follow-up, and complaints, we ensure the quality of after-sales service.

Service before selling

Service during selling

Service after selling

Focusing on intelligent lubrication systems

Carefully developed and crafted premium products

Professional and efficient service for each customer

On site application and solutions

and the automatic lubrication system is also widely used in cement, mining, thermal power plants and other fields. Its excellent technology and superb quality have won praise from customers

What We Provide

and reliable lubrication and protection.

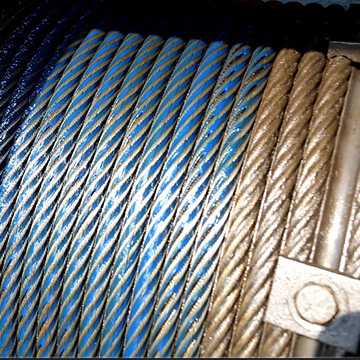

Wire rope cleaner and lubricator kit

It delivers comprehensive lubrication protection, maximizing lifespan. Ideal for high-stress, high-wear, high-cost, and hard-to-replace applications, it cuts costs and enhances efficiency significantly.

Special lubricating grease for maintenance of steel wire rope

Protective intelligent centralized lubrication system

Equipped with a high-compression pneumatic pump and progressive distributor, it offers easy operation, low maintenance, reliable, and optimal protection for machinery.

VMAXX®️Open gear spray lubrication system

By using this system, the lifespan of large and heavy-duty open gear pairs can be improved, downtime can be reduced, and maintenance costs can be lowered.

VMAXX®️Oil & air injection intelligent lubrication system

Other products and components

We also leverage professional expertise and strong R&D capabilities to develop customized lubrication system upgrades tailored to customer needs, enhancing operational efficiency/quality and extending equipment service lifespan.

FAQ

Why does steel wire rope need lubrication and maintenance?

More

Why wire ropt cleaner & lubricator required for the maintenance of steel wire ropes?

More

How to choose VMAXX®️cleaner & lubricator correctly?

More

Why is special lubricating grease required for the maintenance of steel wire ropes?

More

Trouble shooting of wire rope cleaner & lubricator

More

Contact Us

Company Address

Floor 4.2nd Bldg,Sanzao Town,Jinwan DistrictShunyi Technology Park

Tel

+86 756 7255909 +86 13622967989