The VMAXX Light Duty Wire Rope Cleaner & Lubricator is a device designed to maintain and enhance the performance and service life of wire ropes used in various industries. It efficiently cleans and removes scale/dirt from wire ropes while providing lubrication in a fast and safe manner, significantly improving the service life and operational safety of wire ropes. Meanwhile, the VMAXX Wire Rope Cleaning and Lubrication Kit replaces slow and inefficient manual lubrication for wire rope maintenance, delivering fast and effective cleaning and lubrication at a speed of 1,000 meters per hour for wire ropes with diameters ranging from 8mm to 80mm.

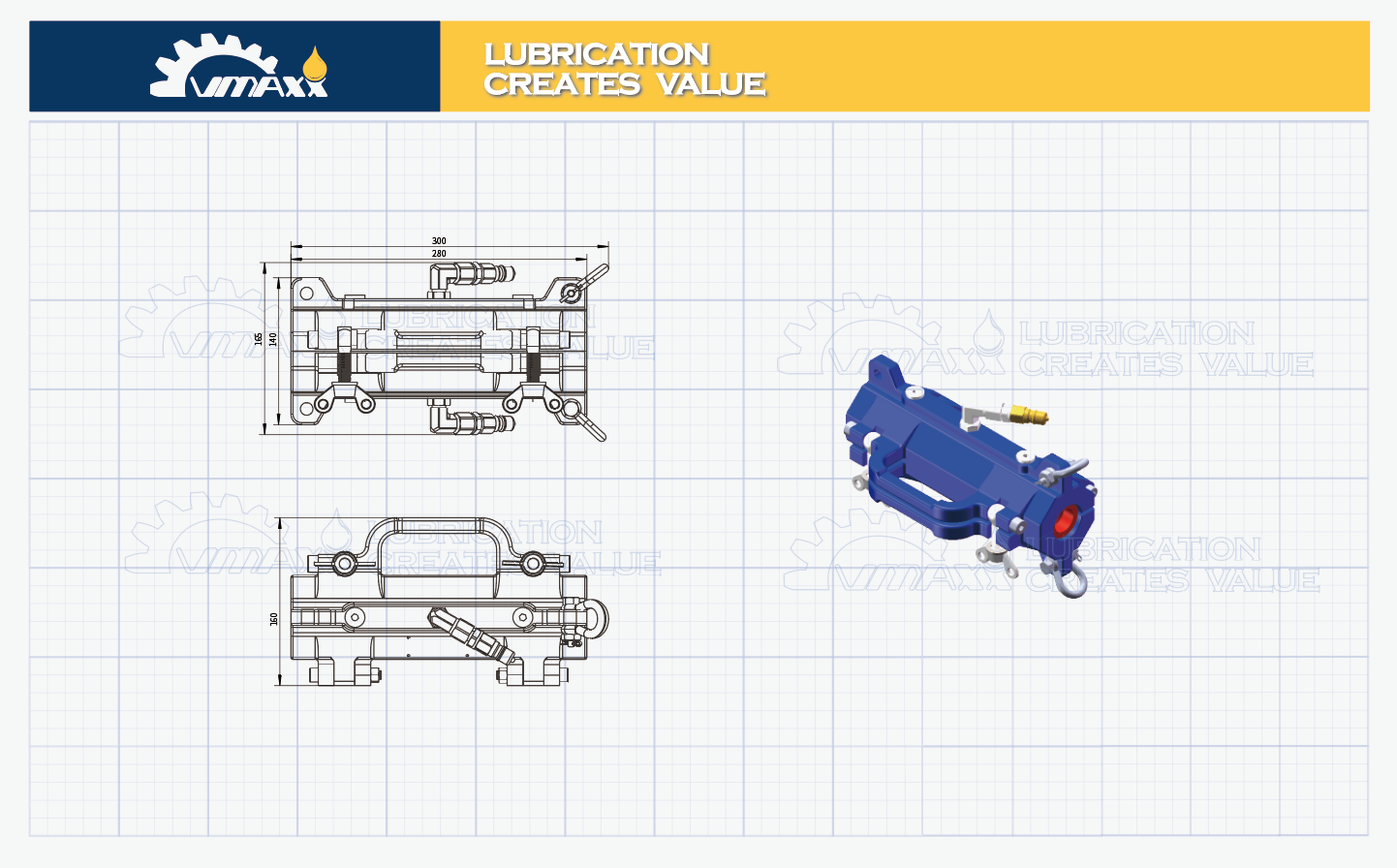

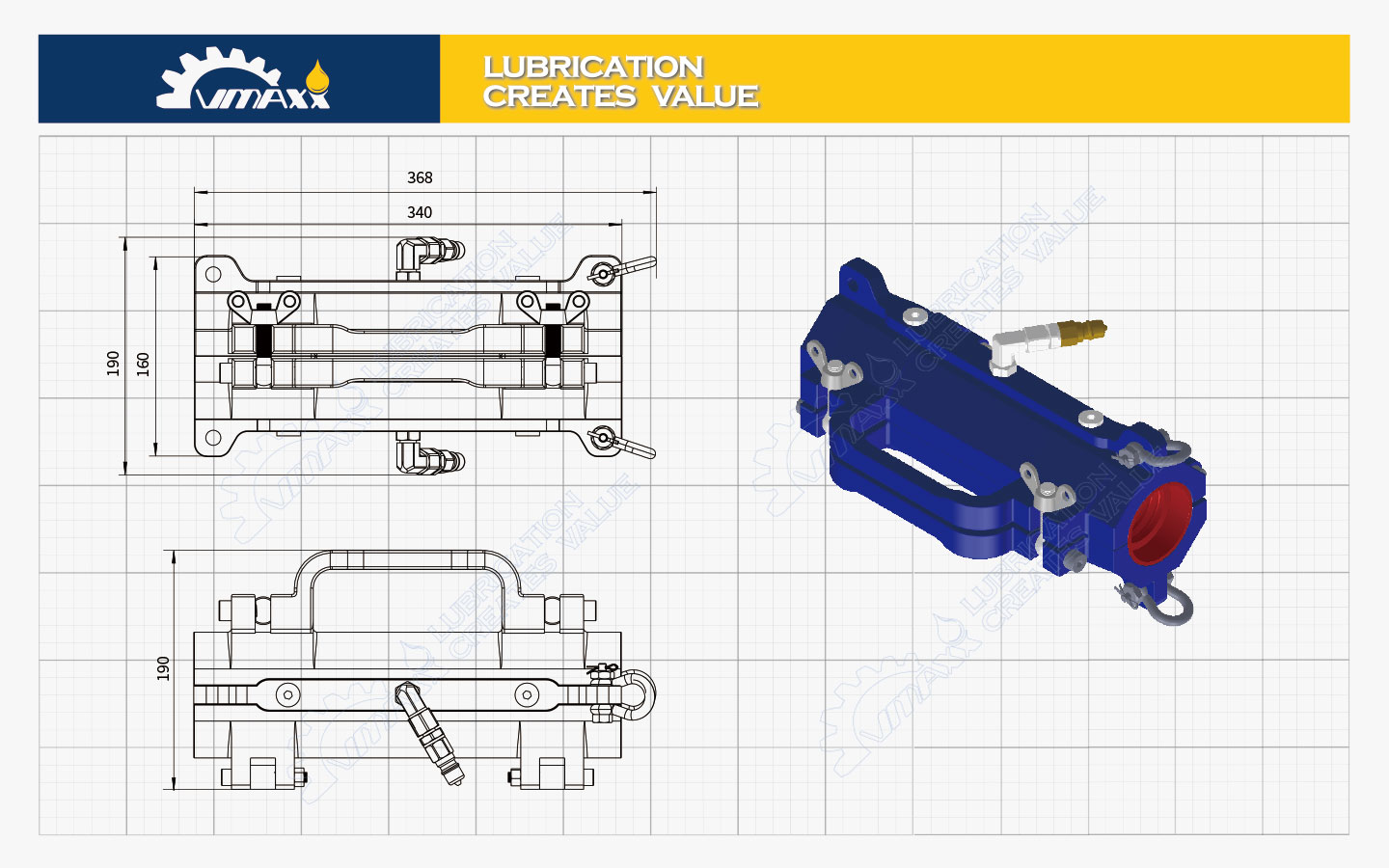

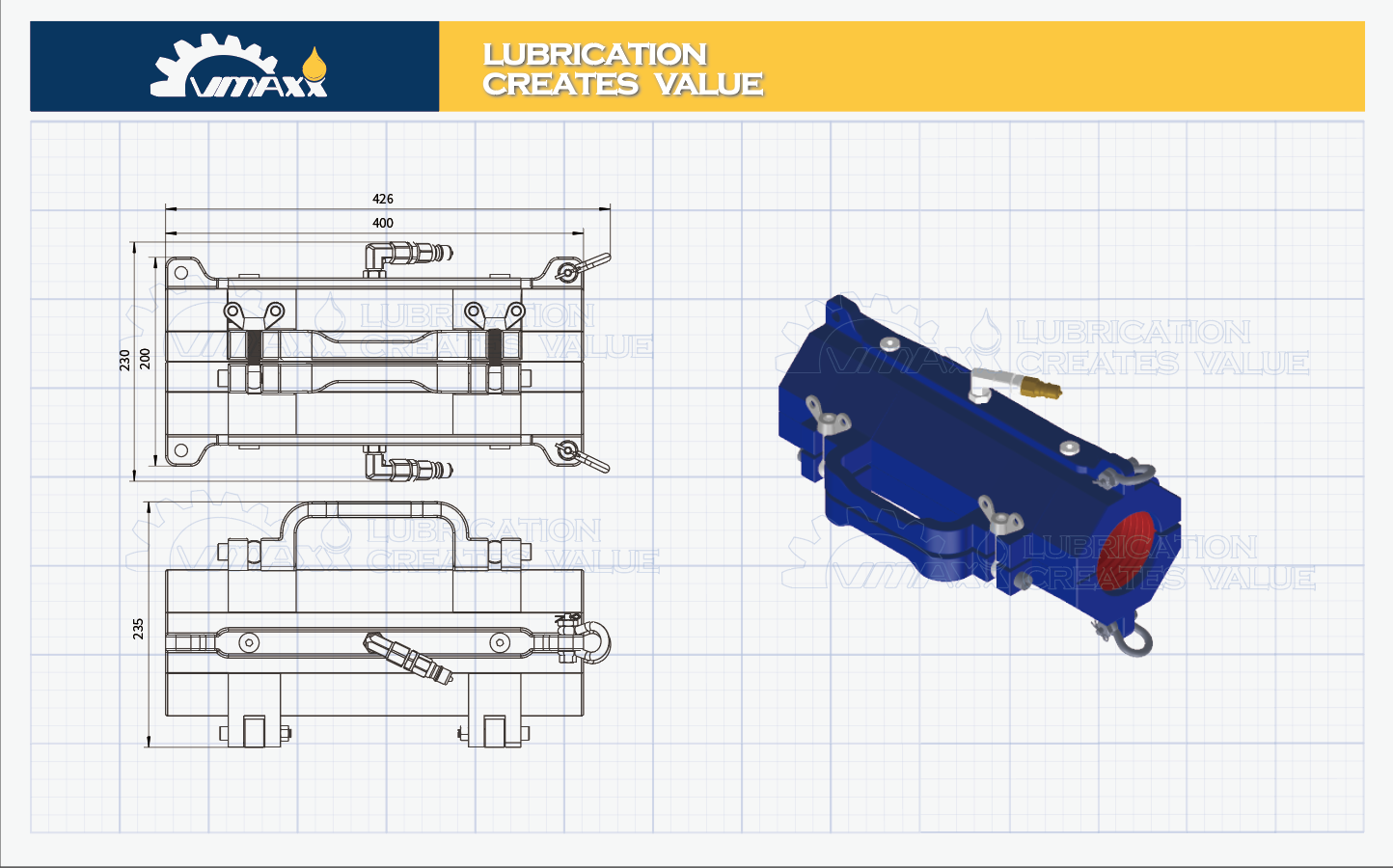

- Compatible Wire Rope Diameter Range: 8 to 32 mm

- Pressure Rating: MAX 500 bar

- Grease Displacement: MAX 1.3 Kg/min

- Suitable Lubricants: NLGI Grade 0# to 2#

- Input Pressure: Compressed Air 3 to 10 Bar

- Grease Container Size: 15 kg

- Gross Weight: 30 kg

- Automatic Lubrication: The wire rope lubricator automatically applies lubricant to ensure consistent and thorough coverage.

- Surface Cleaning Function: Equipped with an automatic cleaning mechanism to remove dirt, debris, and old lubricant, allowing new lubricant to adhere and penetrate effectively.

- Adjustable Settings: Users can customize lubricant output volume and application frequency according to specific operating conditions.

- Extended Service Life: Proper lubrication reduces friction, wear, and corrosion, significantly extending wire rope lifespan.

- Enhanced Performance: Regular lubrication ensures smooth operation, minimizing the risk of breaks and downtime.

- Cost Savings: By prolonging wire rope life and reducing maintenance requirements, the lubricator helps save on replacement costs and downtime.

- Safety Improvement: Well-lubricated wire ropes are less prone to failure, enhancing overall workplace safety.

- Environmental Benefits: Some models are designed to control lubricant usage, reducing waste and minimizing environmental impact.

- Ship mooring ropes, deck equipment, gantry cranes, ROV umbilical cables, cargo cranes, mine hoists, onshore and offshore oil rigs, ship loaders, etc.

- Bridge cranes, mobile cranes, non-destructive testing services, mining hoists, lifting wire ropes.

- Water gates, ship locks, tower stay cables, etc.

Technical Specifications

Product Features and Benefits

Application Industries